Ariterm scrapers

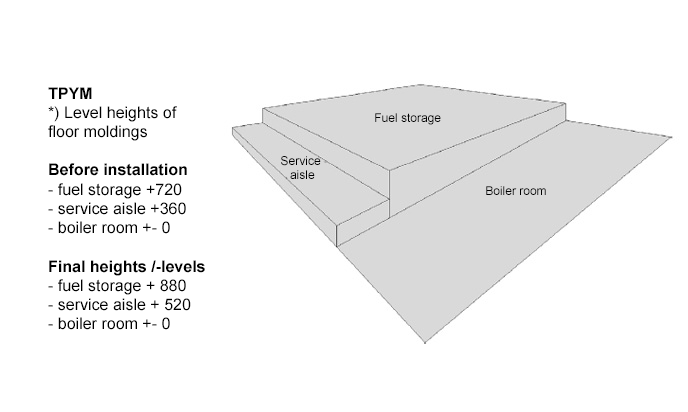

Floor scraper TPYM

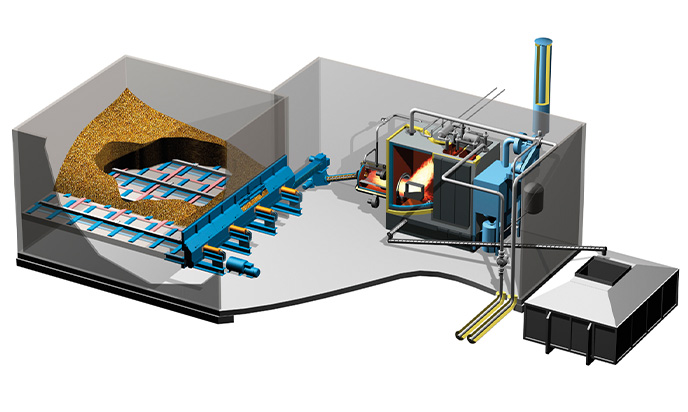

The floor scraper is based on the same technology as the factory-made bar scraper bases, but it is delivered in loose parts. The installation of the dischargers is partially done during the casting. The number and length of the bins can vary, so the floor scraper is very suitable for different storage solutions. The floor area of the warehouse for floor scrapers can vary from 7.5 to 40 m². Storage volume up to 200 m³.

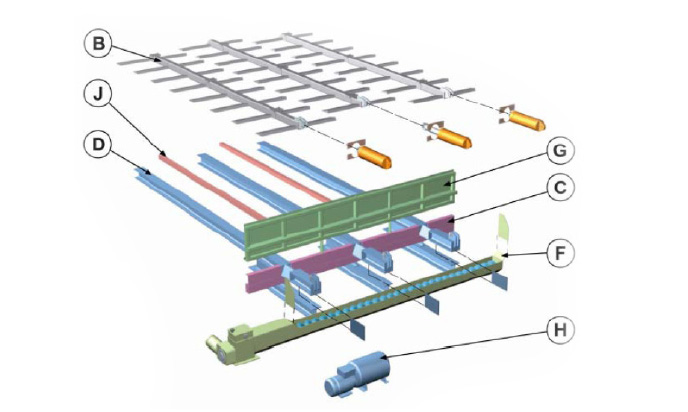

Delivery contents:

- Bottom beams 2-4 pcs. D

- Edge beam (length according to number of blocks) C

- Scraper rods, cylinders (2-4 pcs) and the guide tunnels B for their attachment

- Partition (length according to the number of holes) G

- Stock screw with gear motor F

- Hydraulic unit H

- Counter notches (1-3 pcs/bar spacing) Additional equipment

NOTE! The scope of delivery may vary on a case-by-case basis.

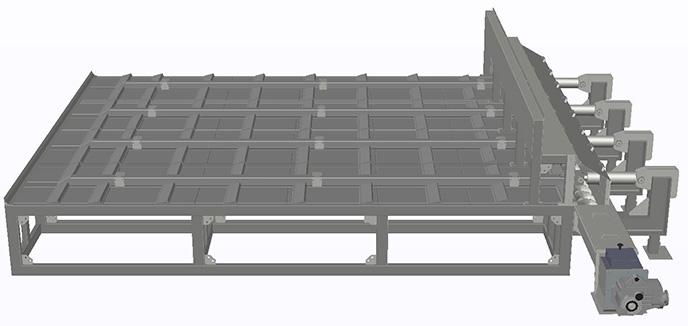

Bar scraper T6

The bar scraper base T6 has a modular structure, the size of the basic part is 1150x5870x1050 mm (width x length x height) and weighs 870 kg. T6 can be expanded to the size of a total of 6 modules, in which case the total width of the scraper bottom is 6900 mm. In this case, the filling interval of the storage can be extended even in larger bio-heating plants. The strong steel structure of the T6 scraper bottom enables the use of T6 with recycling/waste wood. The maximum filling height of the discharge base is determined by the moisture percentage of the fuel: with 20% humidity, the maximum filling height is 5 m and with 45% humidity, 4 m.

The modules are easy to transport in normal freight traffic. At the destination, the modules are connected to each other and the sockets and the storage screw are fixed in place.

Delivery contents:

- Solid steel frame

- Hydraulic cylinders for bar scrapers (2 pcs.)

- Hydraulic unit 1.5 kW

- Storage screw d260 mm + drive motor 2.2 kW

- Storage screw tray width 297 mm and height 329 mm, bar disassembly slots according to the number of selected modules (2 pcs.)

- Each module contains its own inspection hatch limit switch

- AVTA valve

Pellet silos

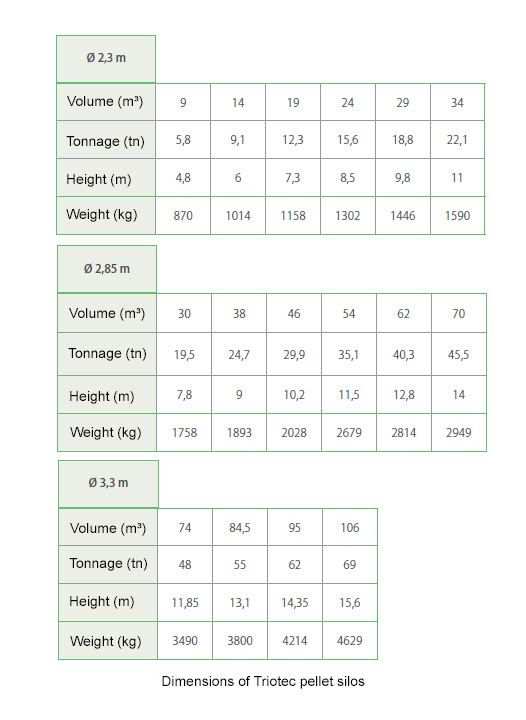

The selection of a technically functional and correctly dimensioned pellet silo is very important as part of the design of the heating center. The silos represented by Ariterm are the result of long-term development work. We can offer a silo solution that suits your needs from numerous volume options and accessories.

The silos are delivered to the installation site as factory-made. The silo is raised upright on top of the foundations and the legs are welded to the casting joints. After this, the silo is ready for use.

The angle of the bottom cone of the blow-filled, cylindrical vertical silo is 60 degrees. A sufficient slope prevents the pellet from arching. There is a dust separation cone on the roof of the silo, which drops the wood dust it has captured back into the silo, thus keeping the environment clean. Careful light surface treatment keeps the pellet cool and the silo looking good.

The inspection glasses on the side of the silo make it easier to estimate the amount of fuel in the silo. When the fuel level falls below the lower limit guard installed in the silo, Ariterm's control automation alerts the operator on duty.

For more accurate quantity measurement, which facilitates the management of fuel logistics in particular, it is possible to install a weighing system in the silos, which, combined with the remote use of control automation, significantly facilitates the plant's operating procedures and monitoring.

The table shows the available silo models. The system is often equipped with two silos, which has the following advantages:

- Better operational reliability

- The possibility of driving a fuel mixture (e.g. wood and peat pellets)

- Scheduling pellet logistics becomes easier

- Two silos often blend better into the environment than a similar volume implemented with one silo

Pellet silos at Halesa Oy heating area in Nokia

Pellet silos at Halesa Oy heating area in Nokia

Determining the volume of the fuel container

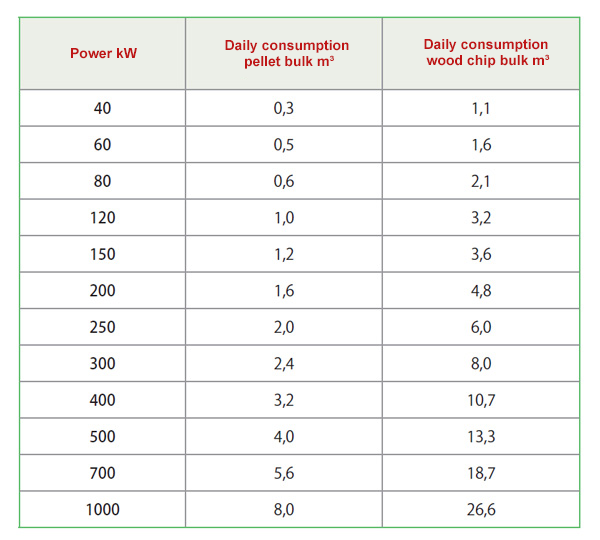

Think about what would be a suitable filling interval, i.e. how often you want to take care of refueling. Choose the storage capacity based on the required filling interval of the fuel storage and the calculated daily consumption (from the table below according to power demand and fuel).

Storage volume = filling interval x daily consumption

The table shows the peak fuel consumption (consumption at maximum continuous power) per day. The storage volume calculated with this value is therefore sufficient for the desired filling interval in the coldest winter season. At other times, the fuel container filling interval is longer.

Contact persons

Project business manager

Maintenance business director, Product and spare parts sales: Bio-products and real estate oil boilers